Quality Assurance

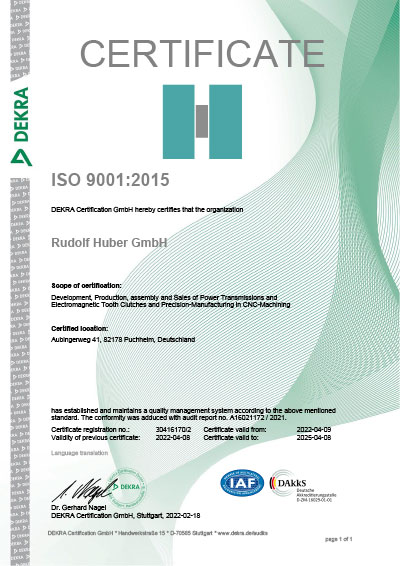

Rudolf Huber GmbH Präzisionsmechanik, manufacturer of drive elements and CNC-machining technology, has established a quality management system according to DIN EN ISO 9001:2015. After a successful audit in March 2016 and a successful recertification procedure in 2019, the certification body of DEKRA has certified our company's compliance with these quality guidelines.

The industry standard DIN EN ISO 9001:2015 is an important quality feature for our customers. It ensures that our company has a well-functioning quality management system and that transparent procedures, efficient processes, clear goals and measurable results are guaranteed.

The certificate is not only the confirmation of previous work, but also an incentive to continuously develop our quality management system.

For the quality control of complex components a 3D coordinate measuring machine of the type THOME PRECISION-RAPID-CNC-PLUS is available with the following features:

• Measuring range LxWxH: 1000 x 600 x 500 mm

• Measuring software XG from METROLOGIC

A number of other testing devices and procedures relate to the fulfillment of the requirements for the assembly of mechanical and electromagnetic couplings:

• Testing of screw connections for torque and angle of rotation

• Functional test of electromagnetic tooth clutches in a climatic chamber

• Measurement of dielectric strength of insulation materials

• Coating thickness measurements

Rudolf Huber GmbH Präzisionsmechanik, manufacturer of drive elements and CNC-machining technology, has established a quality management system according to DIN EN ISO 9001:2015. After a successful audit in March 2016 and a successful recertification procedure in 2019, the certification body of DEKRA has certified our company's compliance with these quality guidelines.

The industry standard DIN EN ISO 9001:2015 is an important quality feature for our customers. It ensures that our company has a well-functioning quality management system and that transparent procedures, efficient processes, clear goals and measurable results are guaranteed.

The certificate is not only the confirmation of previous work, but also an incentive to continuously develop our quality management system.

For the quality control of complex components a 3D coordinate measuring machine of the type THOME PRECISION-RAPID-CNC-PLUS is available with the following features:

• Measuring range LxWxH: 1000 x 600 x 500 mm

• Measuring software XG from METROLOGIC

A number of other testing devices and procedures relate to the fulfillment of the requirements for the assembly of mechanical and electromagnetic couplings:

• Testing of screw connections for torque and angle of rotation

• Functional test of electromagnetic tooth clutches in a climatic chamber

• Measurement of dielectric strength of insulation materials

• Coating thickness measurementsDownloads

Huber product catalog 2019/2020

Everything at a glance!Huber product catalog: HK couplings, slip clutches, miniature couplings, clamping hubs

(Download PDF, 1,2 MByte)

DEKRA Certificate

Download pdf (390 KByte) DEKRA Certificate DIN EN ISO 9001:2015 (English version)

Download pdf (390 KByte) DEKRA Zertifikat DIN EN ISO 9001:2015